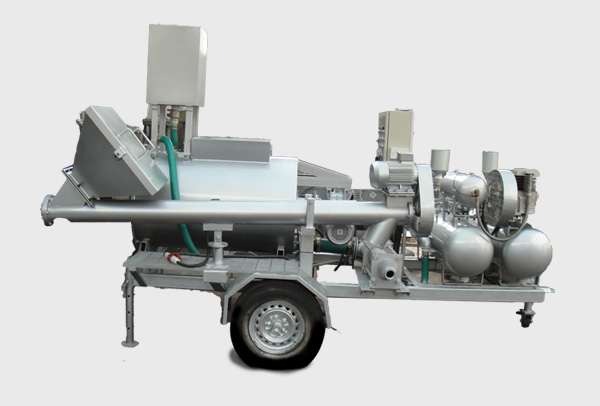

Foam Concrete Machine

A complete mobile unit for mixing, pumping and conveying foam concrete from ground level to the floor or terrace level. The mixing of the suitable materials inside this unit, allows an expansion of foam-concrete up to 5 times of its original volume and its specific weight is thus reduced.

It is therefore ideal for thermal or acoustic insulation of floors. The equipment carries a twin diaphragm pump for pumping the water-foam additive solution, a wider reservoir containing water, the supply hopper feeding the piston pump with cement grout and the mixer-cylinder unit complete with gauges and control valves for production of foam concrete.

SPECIFICATION OF FOAM CONCRETE MACHINE (MODEL: DE-H)

- Mixture tank capacity – 1.35 cubic meter

- Mixture gear RPM 47, mixture motor RPM 1450 HP 5.5

- Chemical tank 2 nos. – capacity 200 liters each

- Stock tank capacity 50 liters

- Air compressor motor RPM 2800 HP 5.5

- Delivery pump motor RPM 1460 HP 20

- Delivery pump with transmission shaft, stator (Type-80 mm), rotor (Type-80 mm) & Pump outlet size- 2”

- Cement feeder motor RPM 1450 HP 4

- Water tank dimension 60 x 80 cm

- Electric control panel board

- Chassis with 5” rectangle tube, chassis length 4.5 meters & width 2 meters, complete machine’s approximate weight 3.2 ton.

SPECIFICATION OF FOAM CONCRETE MACHINE (MODEL: DE-L)

- Mixture tank capacity – 0.60 cubic meter

- Mixture gear RPM 47, mixture motor RPM 1450 HP 5.5

- Chemical tank 2 nos. – capacity 200 liters each

- Stock tank capacity 50 liters

- Air compressor motor RPM 2800 HP 4

- Delivery pump motor RPM 1460 HP 15

- Delivery pump with transmission shaft, stator (Type-65.5 mm), rotor (Type-65.5 mm) & pump outlet size-2”

- Cement feeder motor RPM 1450 HP 4

- Water tank dimension 60 x 80 cm

- Electric control panel board

- Chassis with 4” rectangle tube, chassis length 3 meters & width 1.8 meters, complete machine’s approximate weight 1.8 ton..

DUBAI ENGGINEERING FOAM CONCRETE MACHINE

MODEL. DEH-154-13 / DEH-155-14

USER’S IMPORTANT INSTRUCTIONS FOR SAFETY AND PROTECTION OF THE FOAM

CEMENT MACHINE BEFORE STARTING. (ELECTRICAL)

Please read the following instructions carefully and take the actions.

POWER SUPPLY.

- Provide a (5 core x 10mm) cable to supply the 3-phase power (L1 L2 L3 + Neutral + Earth) for the machine. Neutral and Earth must be connected to the machine, otherwise the outlet power socket and the protective system done in the control panel will be disabled.

- It is very important to remember that, this machine’s electrical designed is for 380V.AC. to 400V.AC. and 50 Hz only.

- While the machine is connected to the power source, be sure that all 3-phases are having equal voltage between each other and having equal voltage with the neutral. It can be checked by using of the volt meter and volt’s meter selector switch which are with the panel board of the machine. A 2-phase line supply will damage the motors.

- If the machine is connected to the AC generator’s power source, then check the proper frequency of generator’s current by looking to the panel board’s Hz meter of the machine. It should not be more or less than 50Hz. Keep in mind that, the generator using for the machine, it must be minimum 60-KVA and above.

- An over or lower voltage may result electric motors and other electrical components to overheat or burn. An over or lower frequency will vary the time of air filling/cement loading/material mixing and mix material delivering or may cause of burn electric motors and other electrical components in the control panel of the machine.

- While starting the main pump’s motor to deliver the mixed materials, be careful don’t gear the motor to load until the motor runs in delta position Because this motor has automatic STAR/DELTA starting system in the control pane. To relies this function, must wait 5 to 10 seconds after pressing the START push button or wait until hearing a 2nd sound from the control panel and then gear the motor to load.

- To recognize the correct direction of the motors just follow up the arrow given on the belt over of the main pump’s motor. By turning to left or right of the main isolator on the control panel can be changed the direction of all motors at a time. No need to change any internal wires of the motors or main line’s wires.